LAMILUX

|

From 2007 to 2008 I have done an intenship for 8 month at LAMILUX as working student in the department "Fibre-reinforced plastics"

in Rehau.

Lamilux - Heinrich Strunz Group is a family owned business located in northern bavaria. Its business areas are divided in two main fields:

LAMILUX daylight systems - Active energy managers for sustainable buildings and LAMILUX fibre-reinforced plastics -

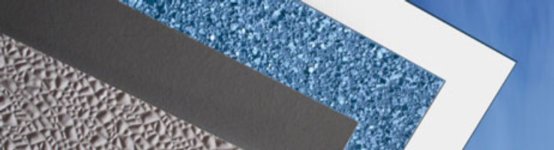

Composites for markets of the future . I worked mainly in the latter area. As an extremely sturdy, yet very lightweight construction

material, the fibre-reinforced composites produced in our continuous, large-scale, industrial flat sheet process offer numerous opportunities

for product developments and is continually opening up new areas of use in dynamic growth markets worldwide: lightweight construction and

energy-efficient mobility, transport and logistics, food industry, modern facade design, portable room systems and temporary buildings.

[Online] LAMILUX [cited at: 10. April 2015.] http://www.lamilux.com/company/about-us.html

For further details see:

LAMILUX

The production process of polymer based composites involves doping fibre mats (e.g. glass, aramid or carbon fibres) in various resins and

chemical additives in a continuous workflow. The mats pass through various stages, during which specific parameters such as thickness,

colour, glass content and curing time are defined. These parameters are decisive for the chemical and mechanical properties of the material.

The result is a highly-durable, permanently bonded composite. Further processing stages, such as cutting to size or corona pre-treatment,

follow for the final product.

During my work I was allowed to see several production steps and involved in the entire quality circle: incoming goods inspection, process control

and final check, laboratory, feedback and statistics.

[Online] LAMILUX. [cited at: 10. April 2015.] http://www.lamilux.com/composites/quality/quality-circle.html

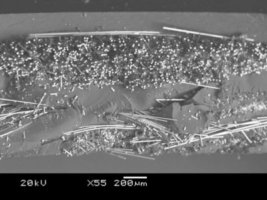

To evaluate the samples I did comprehensive checks and tests to provide a solid basis to further develop fibre-reinforced composites,

analyse their properties and reliably ensure the quality of end products. During this work samples were loaded and analysed using various methods:

- Environmental tests: Artificial aging using infrared and halogen radiation or outdoor weathering

- Chemical and thermal tests

- Fire tests

- Thermography test

- Microscopy

- Gas chromatography

- Impact test

- DMA measurements

- Condensation water test

- Tension/bend strength

- Hardness test (Barcol)

- Surface tension measurement

Fire test

|

Environmental test

|

Chemical and thermal tests

|

LAMILUX [cited at: 10. April 2015.] http://www.lamilux.com/composites/quality/measurement-test-methods.html