Stabilisation in aluminium-based films and foams

Single metallic films were pulled from molten aluminium alloys containing different types of stabilising particles (SiC and TiB2) in a controlled atmospheric chamber using circular molybdenum wire frames in order to discuss stabilisation of metallic foams based on the same melts. Parameters like pulling speed (1-10 mm/s), wire frame size (6-26 mm), particle concentration (0-20 vol.%) and oxygen concentration in the atmosphere (10-8 - 2.1x10+2 ppm) were varied to investigate their effects on film stability. The particle distribution and the thickness of the film lamellae were investigated using optical microscopy. The oxide surfaces of the films were studied by EF-TEM and their role in stabilisation will be discussed. We found that no stable films can be created in the absence of oxygen, even if the melt contains higher particle concentrations or if faster pulling speeds and smallest frame sizes are employed. To pull stable films a minimum concentration of oxygen is necessary. The required oxygen concentration has also an inverse relation with the particle content. Wire frame structures were modified comprising double parallel frames to create artificial metallic Plateau borders on which drainage can be studied. Particle arrangement and movement were observed in-situ via synchrotron X-ray radioscopy. It was found that only liquid metallic alloys containing both Mg and stabilising particles are stable for longer holding times (> 120 s) and sustain drainage. Metal foams from the same alloys were produced by gas injection (Ar or air) for comparison with the results obtained from the film experiments.

K. Heim et al., Procedia Materials Science 4:251-256, 2014

Audioslides of my paper: Stabilisation of aluminium foams and films by the joint action of dispersed particles and oxide films

K. Heim et al., Acta Materialia, 99:313-324, 2015

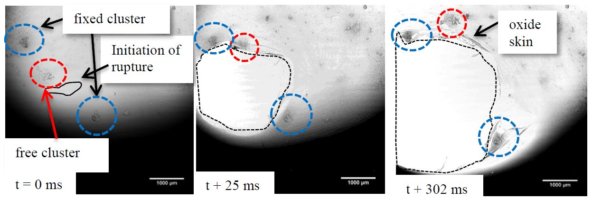

Role of liquid dynamics on the stabilisation of particle-stabilised Al-films

Individual metallic films were pulled from molten aluminium alloys containing different types of stabilising particles (0-20 vol.% of SiC or TiB2). A chamber with a controlled atmosphere (1000 ppm - 2.1x10+5 ppm O2) and different molybdenum wire frame structures were used. Have a look at the entire film pulling process and watch the animation below. The aim was to discuss stabilisation of metallic foams based on the same melts [Heim, 2013]. Beside individual flat films, a modification of the wire frame structure allowed us to create artificial metallic Plateau borders and keep them liquid in order to study melt dynamics. Drainage, the velocity of the propagating rupture as well as the behaviour of the ceramic particles inside the melt were analysed in-situ both visually via a high-speed camera system and by means of synchrotron X-ray radiography. The oxide surface on the films was studied ex-situ by energy-filtered TEM and the particle distribution by metallography and SEM to discuss their role in stabilisation. We found that the particles and the immobile oxide skin, whose formation depends on the level of oxygen in the surrounding atmosphere and the presence of Mg are strongly interrelated. Phenomena such as the healing of thin regions in a film or the fixation of moveable clusters at the immobile gas-liquid interface could be discerned. Interactions of particles and oxygen were also visible during film collapse, where at the oxidised surface fixed particles hinder further film retraction, see upper image. We discuss and compare the results obtained to analogous ones related to both aqueous systems and to metallic foams made from the same alloys by injecting air or Ar into the melt.

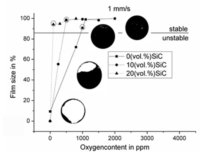

Film size vs. oxygen content. Binarised images of film evolution are

exemplarily shown for the particle-free alloy pulled at 1 mm/s.

K. Heim et al., Procedia Materials Science 4:251-256, 2014 |

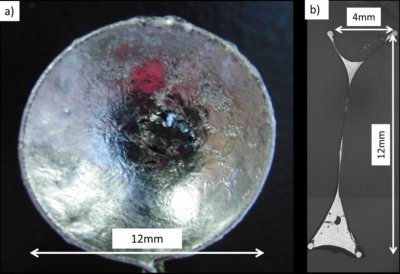

Drainage of particle-stabilised aluminium composites through single films and Plateau borders

Liquid metallic alloys with and without stabilizing particles such as TiB2 or SiC were processed to single films or

artificial single Plateau borders to clarify the stabilization mechanisms of metallic foams based on the same melts.

First, isolated single films were pulled out of a liquid metal by using circular wire frames of various sizes.

Modified wire frame structures comprising double or quadruple parallel frames were then used to create artificial

metallic Plateau borders. Drainage in single metallic films between two Plateau borders was studied by cutting

films vertically and analysing their cross sections. Particle movement in liquid films was observed in-situ via

synchrotron X-ray radioscopy.

It was found that Mg-free liquid metallic alloys containing stabilising particles are

less stable and rupture immediately because of unhindered drainage. In contrast, films made of AlSi9Mg0.6 alloy containing

TiB2 or SiC are stable for long holding times. Our study shows that the complexity of drainage and evolution of Plateau

borders in true metal foams can be studied by using a simple model system based on a single metallic film between two

artificial Plateau borders.

K. Heim et al., Colloids and Surfaces A, 438:85-92, 2013